Nitrogen-doped Graphitic Porous Carbon

₹ 40000 exc. gst

Nitrogen-doped Graphitic Porous Carbon

YAAVIK MATERIALS AND ACS MATERIALS PRESENTS Nitrogen-doped Graphitic Porous Carbon in India.

Product Detail

CAS-No. : 7440-44-0

Rapidly advancing technology has created a need to develop energy storage devices that have the power to efficiently store and supply increasingly high levels of energy. The incorporation of highly electronegative nitrogen into carbon frameworks—known as nitrogen doping—serves to increase the positive charge density of the carbon. This increased positive charge density has a number of positive effects, including extra pseudocapacitance and enhanced surface wettability, surface polarity, and electrical conductivity. In addition, the highly porous structure and large surface area of nitrogen-doped graphitic porous carbon in an electrode facilitates increased access of electrolyte ions and provides copious sites for charge adsorption. Thus, supercapacitors with n-doped electrode materials have exceptional long-term cycling stability, a rapid discharge process, and high specific capacitance.

Nitrogen-doped graphitic porous carbon provided by us is prepared via high-temperature calcination using ZIF-8 as the template and is acid washed to remove the zinc component. In addition to its applications with supercapacitors, n-doped graphitic porous carbon provides the possibility for exciting innovation in other applications, such as photocatalytic hydrogen evolution, pollutant degradation, and CO2 reduction.

1. Preparation Method

ZIF-8 as the template:

1) High temperature calcination

2) Acid-washed to remove the zinc component

2. Characterizations

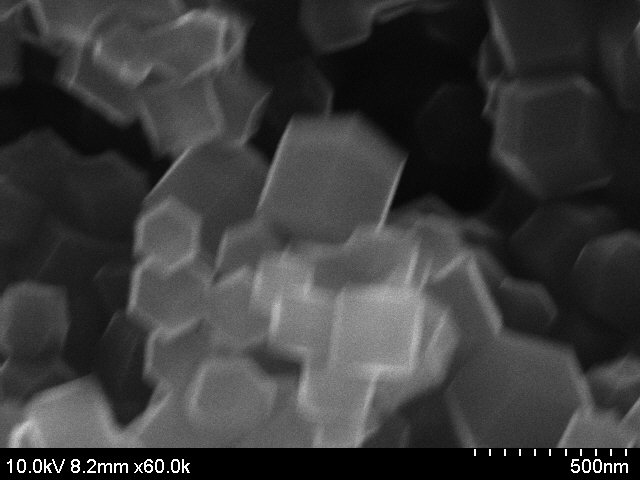

| Appearance: |

Black powder |

| Shape: |

Hexahedron |

| Particle Size (nm): |

200-300 nm |

| BET surface area (m2/g): |

>1100 |

| Total Pore Volume (cm3/g): |

0.74 |

| Pore Size (nm): |

0.3 |

| N (wt.%): |

11 |

Typical SEM Image of N-doped Graphitic Porous Carbon

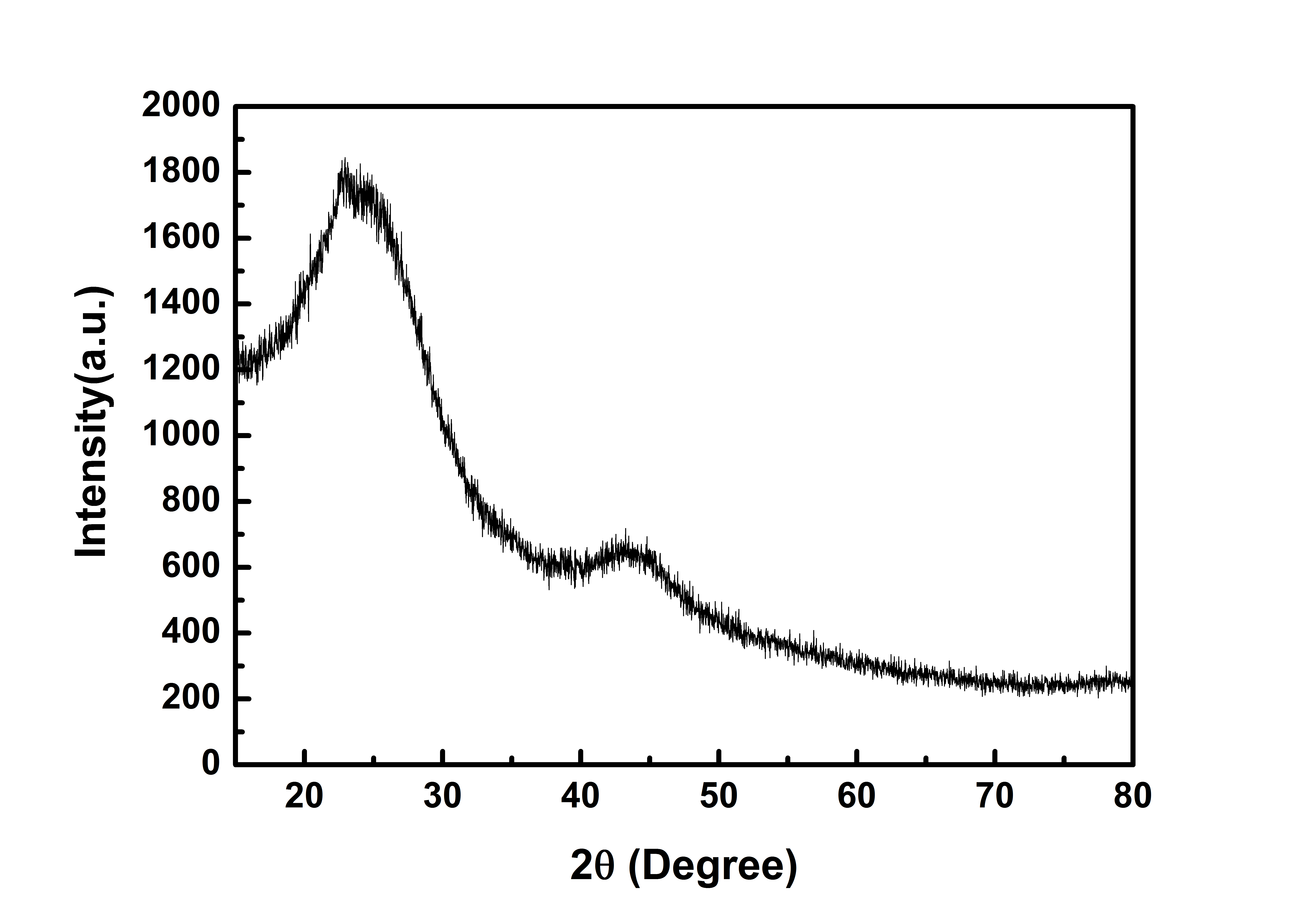

Typical XRD Analysis of N-doped Graphitic Porous Carbon

3. Application Fields

1) Photocatalytic Hydrogen Evolution

2) Pollutant Degradation

3) CO2 reduction

4) Energy Storage

To check out the list of all products visit on https://yaavikmaterials.com/carbon-series/

To visit homepage click on https://yaavikmaterials.com/

Reviews

There are no reviews yet.